A Complete Guide to Freight Container Sizes and Dimensions

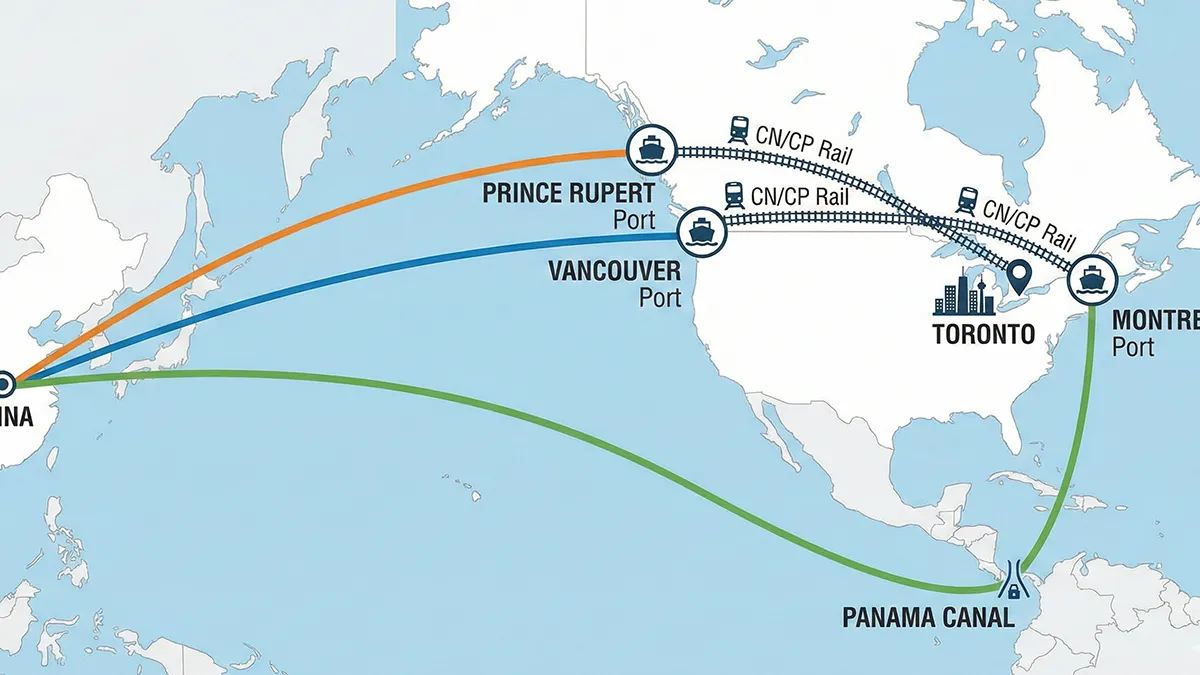

With nearly 90% of the world's goods moving by ship, understanding what is a freight container is fundamental to global trade. These standardized boxes are the building blocks of the entire supply chain, and their vastness is only matched by the massive dimensions of a container ship designed to carry them. For any business importing goods, choosing the right container from the many available freight container sizes dimensions is a critical decision. Picking the correct container sized for your cargo helps protect your goods, manage your budget, and increase overall transportation efficiency.

This comprehensive guide will walk you through the eleven most common types of shipping containers, their specific purposes, advantages, disadvantages, and dimensions, so you can make an informed choice for your next shipment.

Types And Sizes Of Containers

Below are eleven different kinds of containers available for shipping, each serving a unique purpose.

1. Standard Container

-

Purpose: Standard dry containers, made of steel or aluminum, are the most common type in the industry. These are the go-to containers for carrying general dry cargo such as apparel, electronics, palletized goods, and grains. The container standard dimension is designed for intermodal transport.

-

Advantages:

-

Durability: Built from sturdy materials like steel, they are durable and can withstand the harsh conditions of international transit.

-

Intermodal Capability: They are easily transferable between ships, trains, and trucks, simplifying the entire logistics chain.

-

Cost-Effective: As the most common type, they are generally cheaper than specialized containers.

-

-

Disadvantages:

-

Ventilation: They lack any built-in ventilation, which can be a problem for cargo that requires fresh air.

-

No Temperature Control: Standard containers cannot regulate temperature, making them unsuitable for perishable goods.

-

It's crucial to know the internal measurements of a shipping container to plan your load. A key question we often get is, how many pallets fit in 20 foot container? A standard 20ft container can typically hold 10 standard American pallets (40" x 48") or 11 Euro pallets (800mm x 1200mm). For the question of how many pallets fit into a 40 container, the number generally doubles to 20-21 standard pallets or 23-24 Euro pallets.

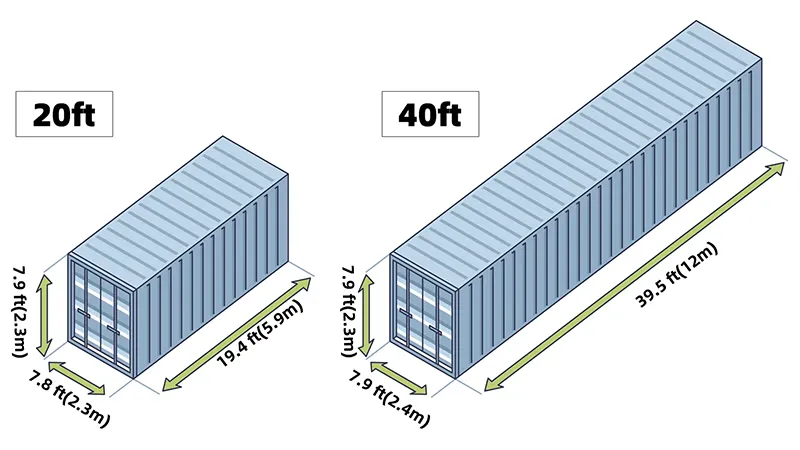

| Dimensions (20ft) | Dimensions (40ft) |

| Inner Length: 5.9m / 19.4ft | Inner Length: 12.03m / 39.5ft |

| Inner Width: 2.35m / 7.8ft | Inner Width: 2.4m / 7.9ft |

| Inner Height: 2.39m / 7.9ft | Inner Height: 2.39m / 7.9ft |

| Tare Weight: 2,300kg / 5,071.5 lbs | Tare Weight: 3,750kg / 8,268.8 lbs |

| Max. Load: 25,000 kg / 55,126.9 lbs | Max. Load: 27,600kg / 61,200 lbs |

| Volume: 33.2 m³ / 1,172 cu ft | Volume: 67.7 m³ / 2,389 cu ft |

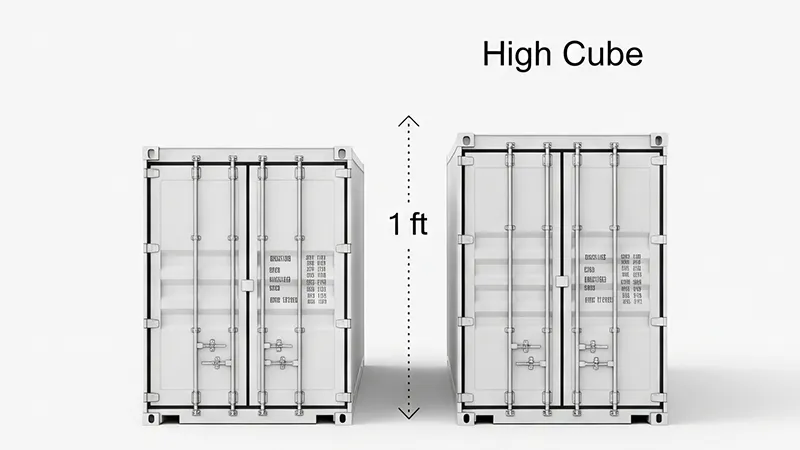

2. High Cube Container

-

Purpose: A 40hq container (or 40 hq) serves the same purpose as a standard 40ft container but offers an additional foot of height. This extra space is ideal for shipping large quantities of lightweight, voluminous items. If you can't quite fit your shipment in a standard container, a High Cube is your best bet.

-

Advantages:

-

Extra Space: The key advantage is the additional vertical space, perfect for taller items or maximizing the load of light cargo.

-

Flexibility: The extra height also makes them popular for non-transport uses like mobile offices or shops.

-

-

Disadvantages:

-

Potential Weight Issues: While spacious, the floor and frame are not designed for significantly heavier loads than a standard container.

-

Compatibility: Some transport systems or depots may not have the clearance to handle the extra height of a 40hq container.

-

Here are the typical 40hq container dimensions:

| 40ft High Cube | 45ft High Cube |

| Inner Length: 12.03m/39.5ft | Inner Length: 13.55m/44.5ft |

| Inner Width: 2.35m / 7.8ft | Inner Width: 2.35m / 7.8ft |

| Inner Height: 2.70m / 8.10ft | Inner Height: 2.70m / 8.10ft |

| Tare Weight: 3,900kg / 8,598 lbs | Tare Weight: 4,800kg / 10,552 lbs |

| Max. Load: 28,600 kg / 63,052 lbs | Max. Load: 27,700kg / 61,067 lbs |

| Volume: 76.3 m³ / 2,694.5 cu ft | Volume: 86 m³ / 3,037 cu ft |

3. Double Door Container

-

Purpose: Also known as tunnel containers, these have doors on both ends. This design is ideal for goods that are bulky or difficult to load and unload, like vehicles, which can be driven in one end and out the other.

-

Advantages:

-

Enhanced Accessibility: Eliminates challenges when moving cargo in tight spaces.

-

Improved Space Utilization: The dual access makes it easier to partition the space and manage cargo from both ends.

-

-

Disadvantages:

-

Limited Availability: These are less common and can be harder to source.

-

Space Consumption: The doors require more clearance to open fully at both ends.

-

4. Open Top Container

-

Purpose: These containers have a removable tarpaulin cover instead of a solid roof. They are used for cargo that is too tall to fit in a standard container or must be loaded from above by a crane, such as large machinery.

-

Advantages:

-

Flexible Loading: Allows for easy loading and unloading of oversized items with cranes or other lifting equipment.

-

Sturdy Floor: Features hardwood or plywood flooring with lashing rings to secure cargo during transit.

-

-

Disadvantages:

-

Cost and Availability: Open tops are more expensive and less available due to lower demand and higher maintenance needs.

-

5. Pallet-Wide Container

-

Purpose: These containers are specifically designed to be about 5 centimeters wider to perfectly fit Euro pallets side-by-side, maximizing space. A standard 20ft container holds 11 Euro pallets, while a 20ft pallet-wide container can carry 15. This is a crucial detail for shippers asking how many pallets in 20 container.

-

Advantages:

-

Space Utilization: Optimizes the use of space for palletized cargo, reducing cost per pallet.

-

Wooden Flooring: Provides high friction to prevent pallets from sliding during transit.

-

-

Disadvantages:

-

Limited Flexibility: The specialized width is less efficient for non-standardized or loose cargo.

-

6. Flat Rack Container

-

Purpose: Flat racks have walls only on the short ends and no roof or sides. They are designed for shipping large, heavy, or oddly shaped items like pipes, machinery, or vehicles that must be loaded from the top or side.

-

Advantages:

-

Easy Loading: The open design allows for simple side or top loading.

-

Higher Weight Capacity: Made from high-strength steel, they can handle extremely heavy loads.

-

-

Disadvantages:

-

Cargo Protection: Cargo is exposed and must be properly covered with waterproof tarpaulins to prevent damage.

-

The 40 flat rack specifications typically feature an inner length of 12.13m (39.8ft), an inner width of 2.40m (7.9ft), and can handle a payload of up to 40,000kg.

7. Side Door Container

-

Purpose: Also called "open side" containers, these feature additional doors along one of the long sides, providing full access to the container's length. This is perfect for loading bulky items with a forklift.

-

Advantages:

-

Efficient Loading: Drastically simplifies loading and unloading with forklifts or pallet trucks.

-

Item Access: Allows for easy retrieval of goods, regardless of where they are placed inside.

-

-

Disadvantages:

-

Less Protection: While the container is weatherproof, the large side doors can be a point of weakness for water leaks if not sealed perfectly.

-

8. Hard Top Container

-

Purpose: Similar to an open-top, but features a removable steel roof instead of a tarpaulin. This offers the top-loading convenience for heavy machinery or fragile oversized items while providing the security of a standard container.

-

Advantages:

-

Secure Top-Loading: Perfect for fragile items that need careful top-loading, with the security of a steel roof.

-

Efficient Stacking: The solid roof allows these containers to be stacked like standard containers.

-

-

Disadvantages:

-

Higher Costs: The heavy-duty construction makes them more expensive than open-top or standard containers.

-

9. Tank Container

-

Purpose: Also known as ISO tanks, these are designed to safely transport bulk liquids, gases, and powders, both hazardous and non-hazardous. They consist of a tank fitted within a standard container frame.

-

Advantages:

-

Environmental Benefits: The sealed structure minimizes the risk of leaks and emissions.

-

Cost Efficiency: Cheaper for bulk liquids compared to using drums or tanker trucks.

-

-

Disadvantages:

-

Limited Versatility: Highly specialized for liquids and gases only.

-

Risk of Contamination: Require rigorous cleaning between uses to prevent contamination.

-

10. Insulated Container

-

Purpose: Designed to maintain a stable internal temperature by protecting the cargo from external temperature fluctuations. They have double walls with a vacuum to stop heat transfer. They do not actively cool the cargo. For example, the inner length of 5.75m to ft is approximately 18.86 feet.

-

Advantages:

-

Energy Efficiency: Reduces the need for external heating or cooling, saving energy.

-

Temperature Shield: The insulation acts as a barrier against extreme heat or cold.

-

-

Disadvantages:

-

Difficult to Clean: Insulation material can absorb liquids and odors.

-

11. Reefer Container

-

Purpose: Reefer containers are essentially mobile refrigerators capable of maintaining a specific temperature, typically between -30°C and +30°C. They are required for perishable goods like fruits, meat, vegetables, and pharmaceuticals.

-

Advantages:

-

Preserving Freshness: Allows for the long-distance transportation of perishable goods.

-

Versatility: Can handle frozen, chilled, or temperature-sensitive cargo.

-

-

Disadvantages:

-

High Cost: The specialized cooling equipment makes them much more expensive to lease and operate.

-

Energy Consumption: Require a constant power supply to maintain the set temperature.

-

Key Container Comparisons

| Flat Rack Container | Open Top Container |

| No sides or top; an open platform | Has sides but no roof; open to the sky |

| Ideal for oversized or very heavy cargo | Ideal for tall items loaded from above |

| Minimal protection from elements | Provides side protection |

| Reefer Container | Insulated Container |

| Actively controls temperature precisely | Passively maintains the initial temperature |

| Can refrigerate, freeze, or heat goods | Protects cargo from external temperature changes |

Frequently Asked Questions (FAQ)

-

1. What are the basic categories of containers?

-

Shipping containers are generally classified into two types: General Purpose Containers (like the dimension container standard for 20ft and 40ft units, and high cubes) and Special Containers (like reefers, open tops, flat racks, etc.).

-

-

2. What are TEU container dimensions?

-

"TEU" stands for "Twenty-foot Equivalent Unit." The teu container dimensions refer to a standard 20ft container, which is approximately 20ft long, 8ft wide, and 8.5ft high. It's the standard unit of measurement for containerized cargo capacity on ships and at ports.

-

-

3. Is there a 53 container size for international shipping?

-

The 53 container size (or container 53 dimensions) is primarily a domestic container used in North America for rail and road transport. It is generally not used for international ocean freight, as container ships and port equipment are standardized for 20ft and 40ft containers.

-

This section is designed for FAQPage Schema.

Choosing the Right Container with an Expert Partner

Selecting the correct container is a foundational decision in your shipping strategy. While a standard container works for most goods, using a specialized container when needed can save you thousands in damaged products and shipping inefficiencies.

As an FMC-registered NVOCC with direct, first-tier (T1) contracts with major ocean carriers, we have access to a full range of container types to meet any shipping requirement. Our end-to-end, one-stop logistics solutions ensure that we not only help you choose the right container but also manage the entire journey from factory to final destination.

Don't leave your cargo's safety and your budget to chance. Contact our team today for an expert consultation.